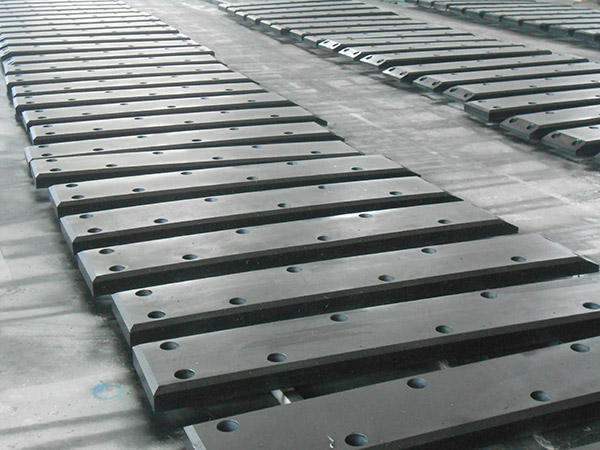

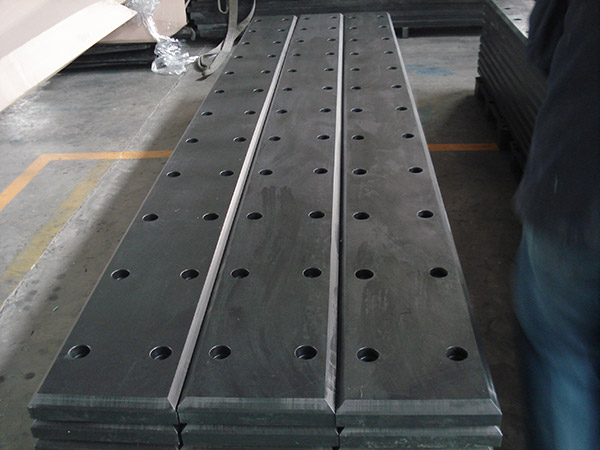

Sliding strips and plates made of Polyethylene are a superior alternative to for example timber and other facing materials as a protective cover for different constructions.

HD-PE does not split or decay and is totally resistant to borers. Environmentally friendly, HD-PE can be used instead of tropical hardwoods, lasts much longer, and can be fully recycled at the end of its useful life.

Features:

● Low friction coefficient

● Resists marine borers

● High abrasion resistance

● UV and ozone resistant

● Does not rot, split or crack

● Easy to cut and drill

● 100% recyclable

They have many applications in waterway, harbour, Wharf constructions, Pontoons, Pier heads and on composite fenders. The Polyethylene is especially useful when low-friction contact during docking and mooring is needed. The Polyethylene does not decay or rot and will not easily splinter or crush.

Applications :

● Fender pile rubbing strips

● Facing strips for berths

● Workboat beltings

● Lock protection

● Lock gate mitres

For these fender strips Fendertec can offer the following two grades of Polyethylene:

HD-PE: High Density Polyethylene

UHMW-PE: Ultra High Molecular Weight Polyethylene

ABOSN manufacture these sliding fenders in dimensions to any requirements from the customer. Beside that we can machine the strips, drill and curved them. We can supply thicknesses from 4mm to 200 mm.

Application: