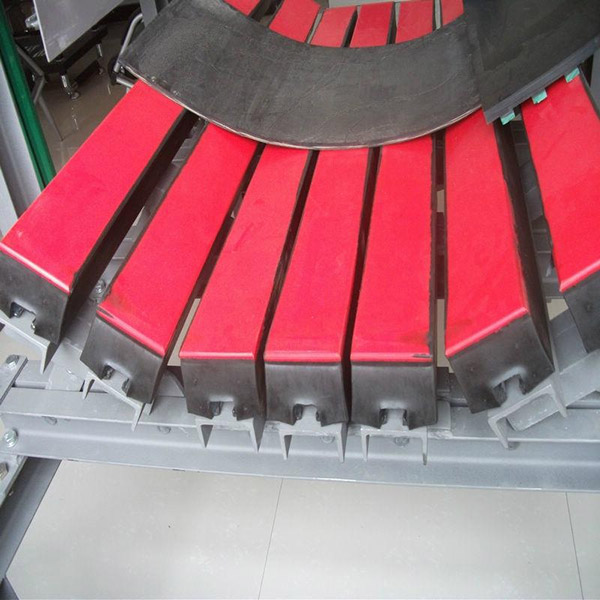

The use of Impact Beds assists the elimination of roller and frame damage in the loading area and effectively reduces belt damage and shock transfer to the conveyor structure. The Bed’s Impact Bars are used to provide a low friction sliding surface between the impact bed and the rubber belt travelling over it. Furthermore, the Impact Bar's rubber backing is designed to absorb impact loads of material on the Bed.

Design Features of Impact Bars include:

Reduces damage to the belt by supporting the entire loading area

UHMWPE polyethylene surface has outstanding wear and sliding properties

Ultra elastic rubber backing absorbs impact

UHMWPE wear strip and aluminium T-Tracker are joined by hot vulcanising during manufacturing process to ensure strong and reliable adhesion

T-Tracker design allows many clamping points along the bar

Available in a variety of different heights (50mm, 63mm, 75mm, 100mm)

Available in two standard lengths (1220mm, 1524mm,1500mm,1800mm )

Can be easily cut to the length required.

UHMWPE features :

The molecular weitht of surface material is more than 500,000,0. With the high friction modulus, good wear resistance, high elasticity rubber, good flexibility. hardness is not greater than 55 degrees to absorb impact energy.

Both ends of theimpact bar is beleved to ensure the belt run smoothly.

UHMW polyethylene surface thickness is 12.5MM or 25MM to meet the different belt speed. unique formula and construction process to ensure a high bond strength between impact bar layer of UHMW and rubber, solid and reliable, and never separated.